In the world of construction and interior design, the quest for materials that combine strength, flexibility, and sustainability has led to the emergence of glass fiber reinforced gypsum (GFRG) panels. These innovative panels offer a unique blend of benefits, making them an excellent choice for a variety of applications, from residential homes to large commercial buildings. In this blog, we will explore what GFRG panels are, how they are made, and why they are becoming a popular choice in the construction industry.

What Are Glass Fiber Reinforced Gypsum Panels?

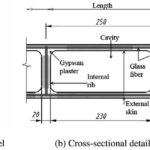

Glass fiber reinforced gypsum (GFRG) panels are lightweight, durable building materials made by combining traditional gypsum plaster with glass fibers. The incorporation of glass fibers into the gypsum matrix enhances the strength, flexibility, and performance of the material, making it an ideal choice for use in walls, ceilings, and other structural applications.

Gypsum, a naturally occurring mineral, has long been used in the construction industry for its fire-resistant properties and ease of use. By reinforcing it with glass fibers, the resulting material offers superior strength without adding significant weight, allowing it to be used in a wide range of building projects.

How Are GFRG Panels Made?

GFRG panels are created through a process that involves mixing gypsum plaster with glass fibers and other additives. The mixture is poured into molds, where it is allowed to set and harden. Once the panels have cured, they are ready for use in construction.

The glass fibers in GFRG panels provide several advantages. They improve the material’s tensile strength, making it less prone to cracking or breaking under stress. Additionally, the fibers help reduce the weight of the panels, making them easier to handle and install, while maintaining the strength and durability required for structural applications.

Key Benefits of Glass Fiber Reinforced Gypsum Panels

- Enhanced Durability: One of the main advantages of GFRG panels is their increased durability compared to traditional gypsum board. The glass fibers add strength and resistance to impact, reducing the likelihood of damage from bumps or accidental impacts.

- Lightweight: Despite their strength, GFRG panels are relatively lightweight, making them easier to transport and install. This reduces labor costs and installation time, making them a cost-effective choice for both residential and commercial projects.

- Fire Resistance: Like regular gypsum, GFRG panels are fire-resistant, making them an excellent choice for fire protection in buildings. They can help slow the spread of flames in the event of a fire, providing valuable time for evacuation and minimizing damage.

- Sustainability: GFRG panels are made from environmentally friendly materials, and their production process has a lower environmental impact compared to many other construction materials. Additionally, the durability of GFRG panels means that they need to be replaced less frequently, reducing waste over time.

- Versatility: GFRG panels are highly versatile and can be used in a wide range of applications, including ceilings, partition walls, decorative features, and exterior cladding. They can be easily molded into different shapes and sizes, allowing for creative and customized designs.

Applications of Glass Fiber Reinforced Gypsum Panels

- Ceiling Systems: GFRG panels are commonly used in ceiling systems, where their light weight and fire-resistant properties make them ideal for both residential and commercial spaces. They can be molded into intricate patterns or left as plain panels, offering design flexibility.

- Partition Walls: GFRG panels are also used for interior partition walls. Their strength and flexibility make them a good choice for dividing spaces in both low-rise and high-rise buildings.

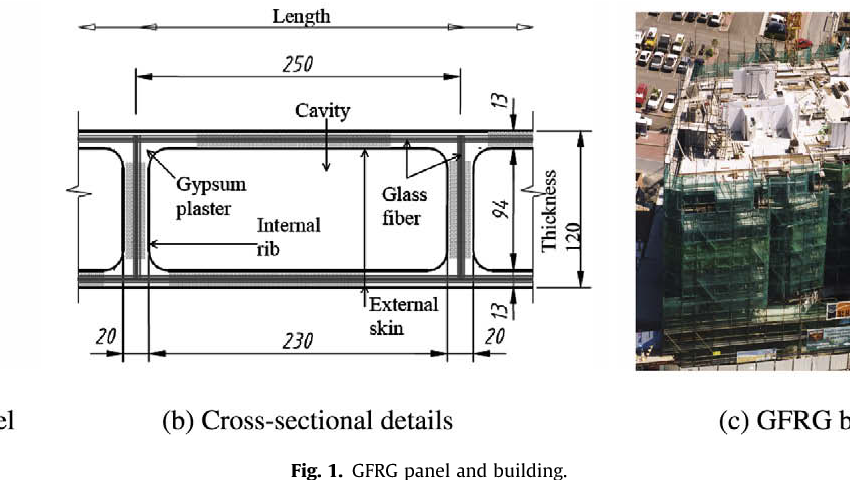

- Exterior Cladding: GFRG panels are increasingly used as exterior cladding materials, offering an attractive and durable solution for building facades. Their lightweight nature and ability to resist the elements make them ideal for a wide variety of architectural styles.

- Decorative Features: The flexibility of GFRG panels allows them to be molded into a range of decorative shapes, making them popular for use in ornamental features such as cornices, columns, and arches.

The Future of Glass Fiber Reinforced Gypsum Panels

As the construction industry continues to prioritize sustainability, energy efficiency, and cost-effective solutions, GFRG panels are expected to play an increasingly important role in shaping modern building designs. With their combination of strength, lightweight nature, and fire-resistant properties, GFRG panels are well-positioned to meet the demands of the industry.

Advancements in material science may also lead to further improvements in the performance of GFRG panels, making them even more durable and environmentally friendly. As the demand for sustainable building materials grows, GFRG panels will continue to be a key player in the construction of safer, more efficient buildings.

Why Glass Fiber Reinforced Gypsum Panels Are the Future of Sustainable Construction

The construction industry is constantly evolving, driven by the need for more sustainable, durable, and efficient building materials. Glass fiber reinforced gypsum (GFRG) panels are gaining popularity as a sustainable alternative to traditional construction materials, thanks to their unique combination of strength, fire resistance, and environmental friendliness. In this blog, we will explore how GFRG panels are shaping the future of sustainable construction and why they are a smart choice for environmentally conscious builders.

The Growing Demand for Sustainable Building Materials

As concerns about climate change, resource depletion, and environmental degradation grow, there is an increasing demand for building materials that are both sustainable and efficient. Traditional construction materials, such as concrete and steel, can have a significant environmental impact, both in terms of raw material extraction and energy consumption during production. The construction industry is now focusing on finding alternatives that minimize these negative effects while still meeting the performance requirements of modern buildings.

GFRG panels are an excellent example of such an alternative. Made from a combination of gypsum and glass fibers, they are lightweight, durable, and energy-efficient, making them a perfect fit for sustainable construction projects.

The Environmental Benefits of GFRG Panels

- Lower Carbon Footprint: The production of GFRG panels has a lower carbon footprint compared to materials like concrete and steel. Gypsum is a naturally abundant material, and glass fibers can be produced using less energy than other reinforcing materials. This makes GFRG panels a more environmentally friendly choice for builders looking to reduce the carbon footprint of their projects.

- Energy Efficiency: GFRG panels contribute to energy efficiency in buildings by improving insulation and reducing the need for artificial heating and cooling. The lightweight nature of the panels means they can be used to create well-insulated walls and ceilings that help maintain a comfortable indoor temperature. This reduces the energy consumption of heating and cooling systems, leading to lower utility bills and a smaller environmental impact.

- Longevity and Durability: One of the key advantages of GFRG panels is their durability. Unlike traditional materials that may degrade over time, GFRG panels are resistant to impact, moisture, and fire, ensuring that they last longer and require less maintenance. This reduces the need for frequent replacements and repairs, helping to minimize the environmental impact associated with construction waste.

- Recyclability: Both gypsum and glass fibers are recyclable materials, which means that GFRG panels can be reused or repurposed at the end of their life cycle. This contributes to a circular economy in the construction industry, where materials are continuously reused rather than discarded in landfills.

GFRG Panels and Green Building Certifications

Many modern construction projects aim to meet green building certification standards, such as LEED (Leadership in Energy and Environmental Design) or BREEAM (Building Research Establishment Environmental Assessment Method). GFRG panels can help builders achieve these certifications by contributing to a building’s energy efficiency, indoor air quality, and overall sustainability.

For example, the use of GFRG panels in a building’s interior and exterior can contribute to credits for energy efficiency, reduced environmental impact, and the use of sustainable materials. This makes GFRG panels an attractive option for developers and architects who are looking to build environmentally responsible structures.

Applications of GFRG Panels in Sustainable Design

- Energy-Efficient Buildings: GFRG panels are ideal for use in energy-efficient buildings, as they provide superior insulation and help regulate indoor temperatures. By reducing the need for energy-intensive HVAC systems, GFRG panels can contribute to significant energy savings over the lifespan of the building.

- Green Roofing Systems: GFRG panels can be used in green roofing systems, where they provide structural support while promoting energy efficiency and rainwater management. Their lightweight nature makes them easy to install, while their moisture resistance ensures that they perform well in varying weather conditions.

- Low-Impact Construction: GFRG panels can be used in low-impact construction projects, where environmental considerations are a top priority. Their durability, ease of installation, and recyclability make them an ideal choice for builders looking to minimize their ecological footprint.

The Future of GFRG Panels in Sustainable Architecture

As the construction industry continues to focus on sustainability, GFRG panels are well-positioned to play a central role in the development of greener, more efficient buildings. With their combination of strength, lightweight design, fire resistance, and environmental benefits, GFRG panels offer a comprehensive solution for builders looking to create sustainable structures.

With ongoing advancements in materials technology, GFRG panels will likely become even more efficient, durable, and environmentally friendly, making them an essential component of future construction projects. As the demand for sustainable building materials grows, GFRG panels are sure to remain at the forefront of the green building movement.

How Glass Fiber Reinforced Gypsum Panels Are Revolutionizing Interior Design

The interior design industry is always on the lookout for materials that combine aesthetic appeal with practicality. Glass fiber reinforced gypsum (GFRG) panels are quickly becoming a favorite among designers due to their versatility, strength, and ability to create stunning visual effects. Whether used for ceilings, walls, or decorative elements, GFRG panels are changing the way we approach interior design. In this blog, we will explore how GFRG panels are revolutionizing interior design and why they are a go-to material for modern spaces.

The Aesthetic Appeal of GFRG Panels

GFRG panels offer exceptional design flexibility, allowing interior designers to create a wide range of decorative features and finishes. These panels can be molded into virtually any shape or size, making them ideal for creating custom designs that complement the overall aesthetic of a space.

- Intricate Ceiling Designs: One of the most popular applications of GFRG panels is in ceiling design. With their lightweight nature and ability to be molded into complex shapes, GFRG panels are perfect for creating ornate ceiling designs, including domes, arches, and decorative cornices. These panels can be combined with lighting elements to create dramatic visual effects, adding a sense of luxury and elegance to any room.

- Wall Paneling: GFRG panels can also be used as wall panels, providing a seamless and sophisticated finish for both residential and commercial spaces. Whether used in living rooms, lobbies, or conference rooms, GFRG wall panels add texture and depth to the walls, giving the space a modern and refined look.

- Customized Decorative Features: The moldability of GFRG panels makes them ideal for creating custom decorative features, such as columns, arches, and ornamental moldings. Designers can easily create unique and personalized pieces that add character and style to a space.

Practical Benefits of GFRG Panels in Interior Design

- Durability and Longevity: GFRG panels are not only aesthetically pleasing but also highly durable. Their resistance to impact, moisture, and fire makes them a practical choice for interior design. They can withstand the wear and tear of daily life while maintaining their appearance and performance over time.

- Ease of Installation: GFRG panels are lightweight, which makes them easier to handle and install compared to traditional materials. This reduces labor costs and installation time, allowing designers and contractors to complete projects more efficiently.

- Improved Acoustic Performance: GFRG panels can be used to improve the acoustics of a space, making them ideal for use in environments such as offices, theaters, and conference rooms. The panels can help absorb sound and reduce noise, creating a more comfortable and productive environment.

- Fire Resistance: GFRG panels offer enhanced fire resistance, making them a safer option for interior applications. They help slow the spread of flames in the event of a fire.

Disadvantages of Glass Fiber Reinforced Gypsum (GFRG) panels:

1. Limited Design Flexibility

- GFRG panels are pre-fabricated, which can limit architectural design freedom, especially for complex or curved structures.

- Customizing panel shapes or sizes for non-standard layouts can be challenging and costly.

2. Specialized Installation Requirements

- Installation requires skilled labor and specialized equipment for proper handling and placement.

- Improper installation may lead to structural weaknesses or alignment issues.

3. Reduced Strength in High-Moisture Areas

- Although GFRG panels are moisture-resistant, prolonged exposure to water or high humidity without proper surface treatment may compromise their durability.

4. Limited Load-Bearing Capacity

- GFRG panels are not suitable for all types of construction, particularly where high load-bearing capacity is required, such as multi-story buildings beyond a certain height.

- Additional structural support may be necessary for heavy loads.

5. Transportation Challenges

- Due to their large size and fragile nature, transportation of GFRG panels can be difficult and expensive.

- Improper handling during transit can cause breakage or damage.

6. Dependence on Specific Infrastructure

- GFRG construction often requires cranes or lifting equipment for installation, which may not be feasible in remote or restricted-access locations.

7. High Initial Cost

- The initial cost of GFRG panels and the associated infrastructure can be higher than conventional construction materials, though this may be offset by savings in time and labor.

8. Limited Awareness and Availability

- GFRG technology is not widely adopted in many regions, leading to limited availability of materials, skilled labor, and technical expertise.

- Local contractors and workers may require training, increasing project timelines and costs.

9. Difficulty in Retrofitting and Modifications

- Making changes or modifications after the installation of GFRG panels can be challenging due to their pre-fabricated nature and structural composition.

- Retrofitting openings for utilities, such as doors or windows, may weaken the panels.

10. Environmental Concerns

- Although GFRG panels are eco-friendly during production, disposal at the end of their lifecycle can be problematic due to their non-biodegradable nature.